Rectangular Connectors - Free Hanging, Panel Mount

Rectangular Connectors - Free Hanging, Panel Mount: Technical Overview & Selection Guide

Definition & Scope

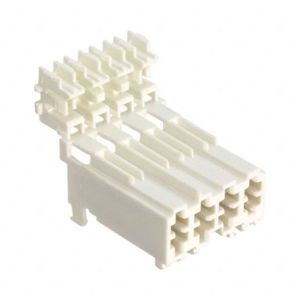

Rectangular Connectors - Free Hanging and Panel Mount are robust interconnect solutions designed for secure electrical and signal transmission in industrial, automotive, and commercial applications. These connectors feature a rectangular interface, offering high-density contact arrangements, mechanical stability, and versatility in both fixed (panel-mounted) and flexible (free-hanging) configurations. They are engineered to withstand environmental stressors like vibration, moisture, and EMI, making them ideal for harsh operating conditions.

Product Types & Variations

This category includes:

1. Free-Hanging (Cable-to-Cable) Connectors: Designed for in-line connections between cables, enabling modular assembly and field repairs. Common subtypes include headers, receptacles, and shrouded connectors with locking mechanisms (e.g., screw-lock or snap-in).

2. Panel-Mount Connectors: Fixed to enclosures or equipment panels, providing secure port interfaces for power/data transfer. Subtypes feature flange-mount, thru-hole, or surface-mount designs with IP-rated sealing for protection.

3. Hybrid Solutions: Combine power and signal contacts within a single housing, reducing footprint in space-constrained applications.

Key specifications include:

- Contact Pitch: Standard (e.g., 2.54mm) to high-density ( 1mm).

- Current Rating: 1A (signal) to 50A+ (power).

- Material: High-temperature thermoplastics or metal shells for EMI shielding.

Purchasing Recommendations

1. Match Environmental Needs: For outdoor/industrial use, prioritize IP67/IP68-rated connectors with corrosion-resistant plating (e.g., gold or tin).

2. Verify Compatibility: Ensure alignment with mating connectors (gender, pinout) and compliance with standards (UL, IEC).

3. Prioritize Locking Features: Screw-lock or latch mechanisms (e.g., M8/M12-style) enhance vibration resistance.

4. Assess Future-Proofing: Modular systems (e.g., modular jacks) allow scalability for evolving connectivity needs.

This category balances durability and adaptability, making it a critical component in infrastructure requiring reliable, high-performance interconnects.

Filter and sort

Categories

3230-40-0104-00

CONN SOCKET 40POS IDC GOLD

3030-20-0102-00

CONN SOCKET 20POS IDC GOLD

2285302

CONN SOCKET 32POS SOLDER TIN

5-103957-3

CONN RCPT 4POS IDC 22-26AWG GOLD

82100-6000

CONN RCPT 100POS IDC 30AWG GOLD

ELRA2A1611

5.7MM EPOWER-LITE 2WAY RECEPTACL

1658622-6

CONN RCPT 26POS IDC 26-28AWG

3421-7020

CONN RCPT 20P IDC 26-28AWG GOLD

4-644083-3

CONN RCPT 13POS IDC 22AWG TIN

86130103130345E1LF

CONN RCPT 10POS IDC 28AWG GOLD

XG4M-2630-U

CONN RCPT 26POS IDC 28AWG GOLD

M80-6132042

2X10POS FEMALE CRIMP LARGE BORE

284865-4

CONN RCPT 4POS IDC 22-24AWG TIN

4-644540-2

CONN RCPT 12POS IDC 22AWG TIN

M80-9435005

CONN RCPT 50POS CRIMP 22AWG GOLD

TCSD-05-01

CONN RCPT 10POS IDC 28AWG GOLD

M80-5C14405MU

CONN PLUG PNL MNT 24-28AWG 44POS

2-353293-4

CONN RCPT 4POS IDC 26-28AWG

89361-144LF

CONN RCPT 44POS IDC 28AWG GOLD

1-282004-2

CONN PLUG 4POS IDC TIN